Specialty Resins

Specialty plastics are those whose properties are tailored to specific applications. Specialty resins take plastic engineering to a whole new level. This class of resins go above and beyond what is indicative of engineered resins, making them perfect for custom plastic parts.

Specialty resins can be blended to achieve enhanced uniqueness and qualities such as fluid plasticity, high performance in extreme temperatures, and liquid penetration. Similar to engineering resins, specialty plastics offer properties that make them great for metal replacement in many industries including plumbing, hardware, and automotive applications.

Diverse Specialty Plastic Options Offer Unique Benefits

Specialty plastics can be manufactured in several different types, each offering their own unique benefits. Specialty resins can be produced as:

- Specialty Elastomers: These materials combine the properties of rubber with plastic, leading to a high level of elasticity, while still maintaining the strength of plastic.

- Specialty Thermoplastic Composites: These materials combine plastic with an extra strengthening element. The reinforced fibers can be fiber glass, metal, or a number of other materials, and are used for applications like noise control or shock isolation.

- Specialty Thermoplastics: These materials are frequently used in injection molding processes because of their ability to be repeatedly melted and remolded.

- Specialty Thermosets: Unlike thermoplastics, specialty thermosets can’t be re-melted or recycled one they are formed. They offer high resistance to heat, however, making them great for heavy-duty applications.

Specialty Resins Provide Additional Properties over Traditional Plastics

Because they are designed for very specific applications, specialty plastics offer a wide range of benefits depending on their composition. They are designed for high-performance applications that need additional properties.

Specialty resins provide benefits like:

- High Strength

- Flexibility

- Viscosity

- Wider temperature range

- Low moisture absorption

Lomont Molding Uses Many Specialty Resins including:

COC: Cyclic olefin copolymer is a specialty plastic that can be used for a wide variety of applications including lenses, touch screens, light guide panels, and even alternative glass in medical packaging. It has a good melt flowability, excellent moisture, heat, and chemical resistance, and high clarity.

COP: Cyclo-olefin polymer is known for its low moisture absorption, making it dimensionally stable even in high humidity environments. It is often used in medical applications because of its high purity, as well as in electric insulating applications.

LCP: Liquid-crystal polymers are very resistant to high temperatures, and are known for being highly resistant to fire. They are also very durable and resist stress-cracking. LCPs are used in many applications including electrical and mechanical parts and food containers.

Delrin®: Delrin is an acetal homopolymer resin that is made specifically for high load mechanical applications. It offers high tensile strength and impact resistance. This specialty resin is great for gears, safety restraints, door systems, conveyor belts, and many other applications and industries.

Contact Lomont Molding to Learn More

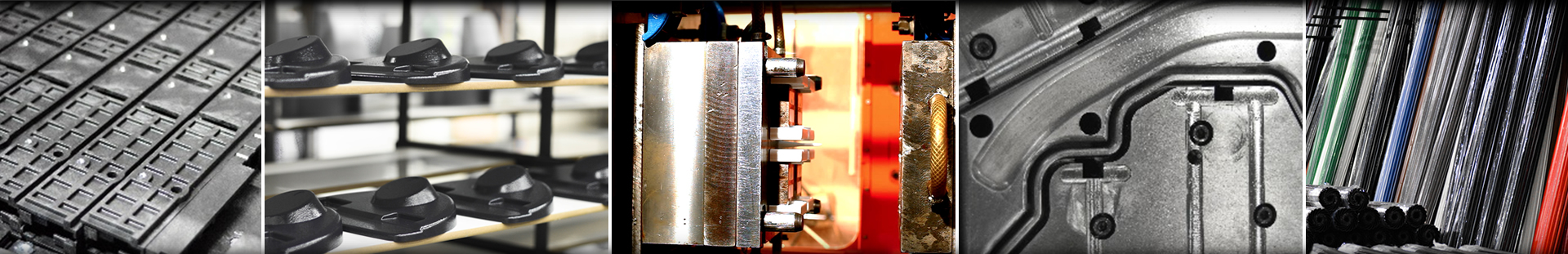

With decades of experience, Lomont Molding offers the expertise and quality assurance you need for your application. We specialize in plastic molding, and offer complete, in-house services.

To learn more about our specialty resins, or to find the right material for your project, contact us today.