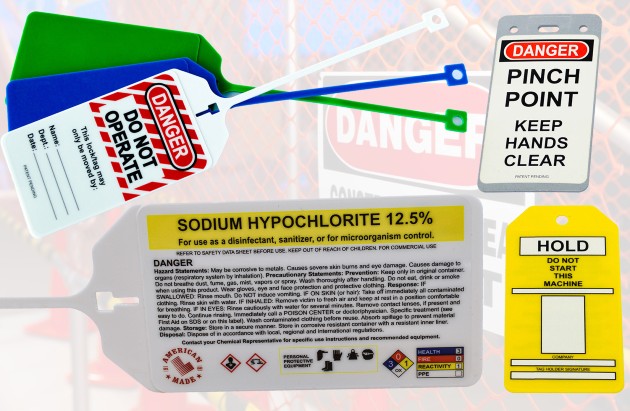

Custom-Molded Tags for Harsh Environments

From chemical ID to process control and beyond, our industrial tags are built to last: no peeling, fading, or breakdown over time.

Tough Tags for Critical Applications

At the core of Lomont IMT’s product line is our custom-molded industrial tag. Our tags are used widely across chemical processing, sanitation, food production, and countless other industries.

Designed for durability and clarity, these tags are resistant to abrasion, harsh cleaners, and extreme conditions.

While chemical identification is our most common use case, our tags are also ideal for equipment labeling, inspection tracking, visual management, and even creative applications like cattle ID or asset tracking. If it needs to be tagged and it needs to last, this is the solution.

Molded for Durability

These aren’t printed or laminated. Our tags are manufactured with permanent, in-mold graphics that stand up to abrasion, chemicals, UV, and pressure washing. No peeling. No smearing. No replacements every six months.

Tailored to Your Operation

We work with your team to create tags that match your process; from chemical IDs and line labels to serialized equipment tags or inspection markers. Any size, layout, iconography, or language can be built in.

Flexible Use Cases

Most of our customers use tags for chemical labeling, but our capabilities go well beyond that. We’ve produced durable tags for valve identification, sanitation steps, cattle tagging, and more. If you can describe it, we can build it.

Sized and Customized to Fit

Our tags are available in a range of standard molded sizes, including popular formats like 3×5.75″ and 3×9″, with various color options to support sorting, categorization, or visual management. We also offer multiple mounting options depending on your application; from hangtags and adhesive backing to tagless strap solutions and more. Whatever your environment, we’ll help match the right combination of size, color, and attachment for the job.

CASE STUDY

Lockout Tagout Placarding for Leprino Foods

Leprino Foods, a leading manufacturer of cheeses and other dairy products, needed durable lockout tagout placards for their production equipment. They needed signs that were highly visible and that made their safety processes easy to understand.

However, since Leprino’s plants require five to six hours of cleaning every day, management knew that ordinary safety signage would not be up to the task. Finding signs that could survive the company’s rigorous cleaning regimen presented a unique challenge. That’s where Lomont IMT came in.

After working with a lockout/tagout consulting firm to devise proper graphical representations and wording for their lockout tagout instructions, Leprino turned to Lomont to produce the placards. Using injection molding and in-mold technology (IMT), we fused Leprino’s graphics and the plastic backing of the placards into solid, one-piece signage.

After field-testing, accelerated weathering tests, and liquid penetrant inspection testing, we and Leprino were confident that the signs could withstand both the tough working conditions of Leprino’s manufacturing plants and their related sanitation routines. After 8 months, the placards are still in place and have held up to the vigorous cleaning schedule.

As an added safety measure, we manufactured Leprino’s lockout/tagout signs with metal compounds molded directly into the plastic. This way, if a sign were accidentally fractured, any pieces that may break off and fall into their product stream can be easily detected and discarded.

This proved to be a key design feature, allowing Leprino to post equipment specific lockout tagout procedures on production equipment near food products where lockouts are regularly performed.

Start Your Custom Tag Project

From high-volume chemical labeling to one-off specialty applications, IMT industrial tags are built to meet your needs.