Nitrogen Gas-Assist Molding

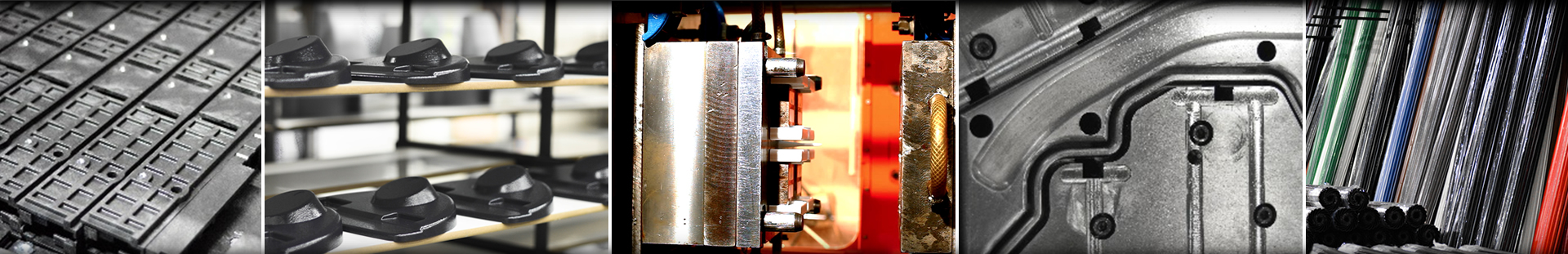

Gas Assist Thermoplastic Molding is a smart option for clients who are not only looking to save on time and overall cost, but are also looking to mold parts that have a superior surface appearance and are lighter in weight. For over 17 years Lomont Molding LLC (Lomont) has offered Nitrogen Gas Injection Molding technology for a diverse range of applications.

Gas Assist Molding Process

Gas Assist Injection Molding is a process that utilizes nitrogen gas, which results in the dispersion of the gas throughout the entirety of the reinforced mold. This process can produce large plastic parts with multifaceted designs and outstanding cosmetic surface finishes.

Gas Assist Thermoplastic Molding works by displacing molten resin from sections of the part toward areas in the cavity that are last to fill. The nitrogen gas pressure thus creates channels, so the pressure can be evenly transmitted across the part; eliminating warpage, sink marks, and internal stress. As a result, this significantly reduces clamp tonnage, cycle time and part weight. A reinforced molded part also benefits from increased strength and rigidity. In addition, Gas Injection Molding allows molders the freedom to design plastic parts without some of the restrictive limitations inherent in conventional molding.

Thermoplastic Molding Eliminates Sink Marks

Lomont’s gas injection molding process can create thin-wall parts with heavy ribs, bosses, and gussets. This nitrogen injection method allows the parts to be formed to a high standard of flatness, without sink marks, or long cycle times. Additionally, long shapes are produced without multiple drops or hot runner systems. This eliminates knit lines and lowers tooling costs. Moreover, multiple parts of a complex design and differing wall thickness are molded as a single part.

Gas Injection Molding Applications

There are numerous applications that benefit from Gas Assist Thermoplastic Molding, some of which include:

- Automotive Interior

- Spools

- Traffic Devices

- Thick Wall Parts

- Appliance handles

- Medical equipment housings

- Basketball backboard frames

- Steering wheels

Gas Injection Molding Benefits

Gas Assist Technology offers many design and performance advantages over other large part molding processes. Multiple parts with differing wall thickness and complex designs can be molded as a single part with tighter tolerances. For these reasons, parts exhibit improved dimensional stability and higher quality surface cosmetics, while requiring minimal or no secondary operations. The benefits of Nitrogen Injection Molding, include:

- Reduced Weight of Part

- Shorter Cycle Time

- Fewer Materials Used

- Increased Strength and Durability

- Improved Surface Appearance

- Gives Reinforcement to Ribbed Parts

Cost Saving Benefits

Gas Assist Thermoplastic Molding typically requires roughly one-third the clamping force of standard injection molding. Thus, the same part size may be processed with a lower tonnage press, which provides you the ability to keep part costs down, while introducing less residual stress into the part. In addition, reduced in-mold pressure subjects the mold to less wear and tear, which extends the tooling life. Gas injection molding parts also weigh considerably less, which results in overall reduced shipping expenses and enhanced material handling proficiencies.

Thermoplastic Resin Materials

There are several distinct types of resins that can be used in the Gas-Assist Molding process, these include:

- PC (Polycarbonate)

- PP (Polypropylene)

- ABS (Acrylonitrile Butadiene Styrene)

- PA (Nylon)

- HIPS (High Impact Polystyrene)

- PET (Polyethylene Terephthalate)

- PPE (Polyphenylene Ether)