Tooling & Molding

Tooling Expertise and Molding Excellence Under One Roof

From tool management and mold maintenance to high-performance production molding, we support your part through every stage of its lifecycle.

Precision Tooling and Reliable Molding Built to Perform

At Lomont, we provide comprehensive tooling and molding support to help customers achieve consistent part quality and long-term production success.

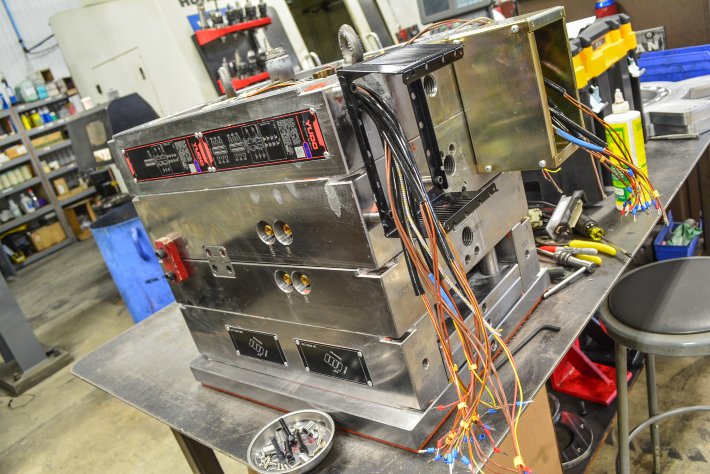

While we partner with trusted mold builders for most new tooling, our in-house toolroom is equipped for full-scale maintenance, repairs, and engineering changes.

We offer a seamless path from tool prep to final part, combined with our broad molding capabilities and press ranging from 30 to 2700 tons.

A Smarter Approach to Tooling and Molding

Tool Management and Maintenance

We manage and maintain a wide variety of tools for customers across industries. Our in-house toolroom is equipped with advanced machining, polishing, and EDM capabilities, allowing us to provide preventative maintenance, troubleshooting, and full tool repairs without delays.

Engineering Support for Tooling Success

Our team evaluates and supports each new tool to ensure optimal fit, function, and processability. We work closely with our external tooling partners and internal engineering teams to ensure all customer requirements are met before the first shot.

Molding Capabilities to Match Your Needs

We run a wide variety of thermoplastic materials using multiple molding methods, including high-pressure injection, structural foam, over-molding, blow molding, and gas-assist. With press sizes up to 2700 tons, we’re equipped to mold small, intricate parts or large, high-strength components with equal efficiency.

Lifecycle Support and Engineering Changes

Tooling doesn’t end after production begins. We provide ongoing support for tooling modifications, engineering updates, and component revisions to keep parts current, efficient, and reliable throughout the product lifecycle.