Quality

Quality You Can Measure And Trust

Our commitment to quality goes beyond compliance. With robust systems, trained personnel, and ISO 9001:2015 certification, we deliver consistent, reliable results across every project.

Built-In Quality from Start to Finish

At Lomont, quality isn’t an afterthought, it’s embedded in everything we do.

From raw material sourcing to final inspection, we maintain strict process controls and quality protocols to ensure every part meets your expectations.

We combine hands-on expertise with advanced monitoring systems to deliver performance you can rely on batch after batch, part after part.

Our Quality Process in Action

Certified Systems and Trained Staff

Our quality system is certified to ISO 9001:2015 and is implemented by a dedicated team of trained professionals. Regular audits, employee training, and continuous improvement programs ensure our system remains effective and aligned with industry best practices.

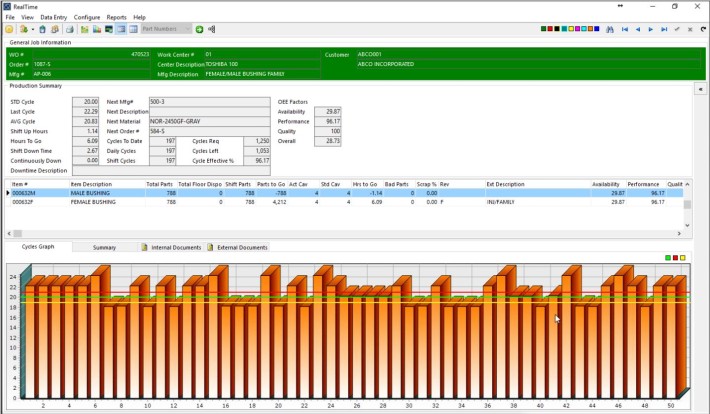

ERP-Driven Traceability

Our IQMS ERP system tracks every part from start to finish, providing complete traceability across materials, tooling, machines, and operators. This level of visibility ensures accountability, rapid issue resolution, and seamless customer communication.

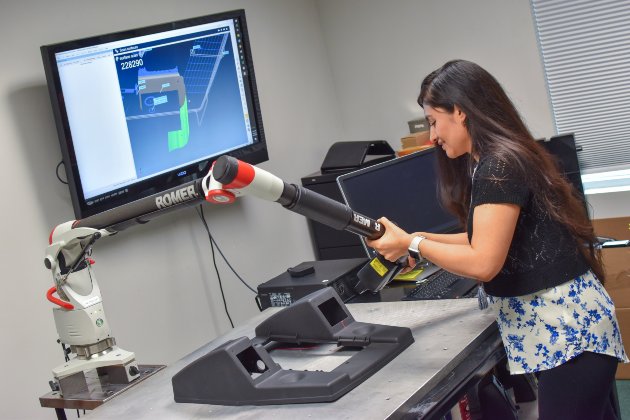

In-Process and Final Inspection

Parts are inspected at every stage of the process before, during, and after molding. We use calibrated gauges, visual inspection protocols, and automated systems where appropriate to verify key dimensions, appearance, and performance criteria.

Customer-Focused Documentation

We support your quality requirements with detailed documentation; from control plans and PPAP packages to inspection reports and certificates of compliance. Our team works with yours to ensure all regulatory or industry-specific standards are met.