Engineering Services & Automation

Engineering-Driven Solutions with Integrated Automation

From part design to automated production, Lomont’s in-house engineering and automation capabilities ensure consistent quality, efficient workflows, and cost-effective outcomes.

Engineered For Your Needs

At Lomont, engineering is a core driver of product quality, process efficiency, and innovation.

Our experienced team helps optimize part design for manufacturing success; whether starting from scratch or refining existing models. We pair this expertise with advanced automation throughout our production floor to reduce cycle times, improve consistency, and minimize manual handling.

This combination helps us support complex and high-volume projects with precision and repeatability.

Engineering and Automation at Lomont

Engineering and Automation at Lomont

Our engineers work closely with customers to ensure each part is optimized for manufacturability, from material selection to part geometry. We identify opportunities for automated processes, streamline workflows, and apply DFM principles to reduce complexity and cost without compromising quality.

CAD and Simulation Expertise

Our team leverages SOLIDWORKS®, KeyCreator, and Mastercam to create precise, production-ready part designs. We utilize mold flow analysis and simulation tools to improve tool performance and reduce launch risk.

Rapid Prototyping and Pre-Production Support

We offer in-house prototyping options including CNC machining, RTV silicone molding, and 3D printing to evaluate form, fit, and function before tooling commitment.

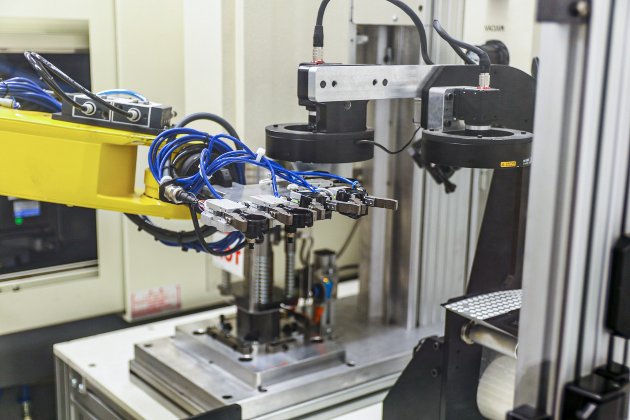

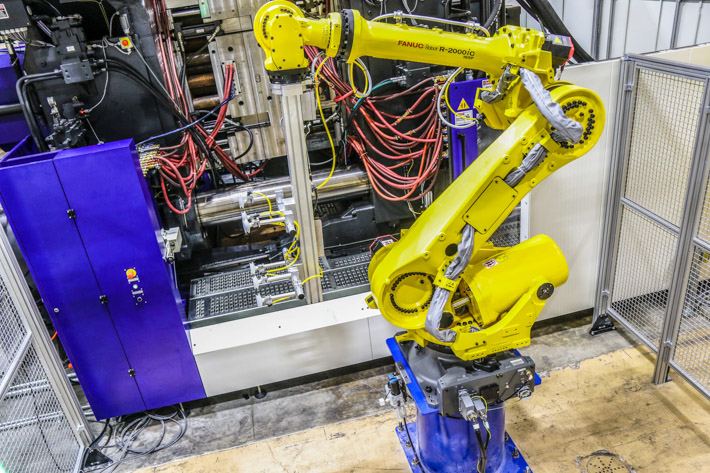

Automated Part Handling and Insert Loading

We integrate automation into key production stages like insert loading, pick-and-place, and material handling. This reduces operator variability and enhances cycle time efficiency.

Post-Mold Automation and Finishing

Automation extends beyond molding with systems designed to snap lids, apply labels, load trays, and more, helping streamline workflows and reducing labor demands across secondary operations.