Early Supplier Development

Setting Projects Up for Success from the Start

Our Early Supplier Development approach helps customers launch better products faster, smarter, and with fewer costly revisions.

Collaboration That Delivers Long-Term Results

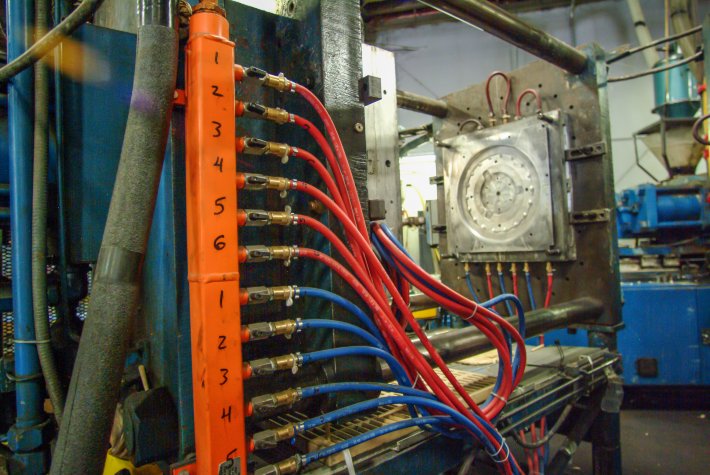

At Lomont, we don’t just manufacture, we partner. Our Early Supplier Development (ESD) process is designed to bring our manufacturing insight to the table early in your product lifecycle.

By engaging at the design or pre-tooling phase, we help optimize part geometry, material selection, and manufacturing feasibility leading to faster tooling, fewer engineering changes, and higher production success rates.

What Our Early Involvement Means for You

Design for Manufacturability (DFM)

Our engineers provide feedback on part geometry, draft, wall thickness, gating, and other key factors that impact tool life, cycle time, and part quality; helping refine designs before tooling ever begins.

Material and Process Guidance

We help customers choose materials that match performance needs, regulatory requirements, and cost goals. Whether you need chemical resistance, flexibility, impact strength, or FDA compliance, we offer insight based on real-world molding data.

Tooling Risk Reduction

By identifying manufacturing risks early, we help eliminate guesswork in the tooling phase. Our ESD process reduces rework, improves tooling outcomes, and supports smoother first-article approvals.

Accelerated Timelines

Involving Lomont early means fewer surprises down the road. Our proactive involvement helps streamline your project schedule, so you can get from concept to production faste with fewer delays or revisions.