Assembly and Secondary Operations

In-House Assembly & Secondary Operations That Deliver More Value

Lomont integrates post-molding services like painting, welding, and final assembly to reduce outsourcing and shorten lead times.

End-to-End Support Beyond Molding

At Lomont, we go beyond molding to deliver full-service production capabilities through our robust in-house secondary operations department.

From part painting and welding to complete sub-assembly, our capabilities ensure every molded part leaves our facility ready for the next stage.

This integrated model eliminates delays, lowers costs, and ensures consistent quality control across the entire production process.

Secondary Capabilities That Add Value

Innovation and Continuous Improvement

Our in-house access to post-molding processes opens doors for customer collaboration and development. Whether it’s exploring new material pairings, experimenting with design improvements, or refining production techniques, our secondary operations enable faster innovation, continuous improvement, and rapid prototyping.

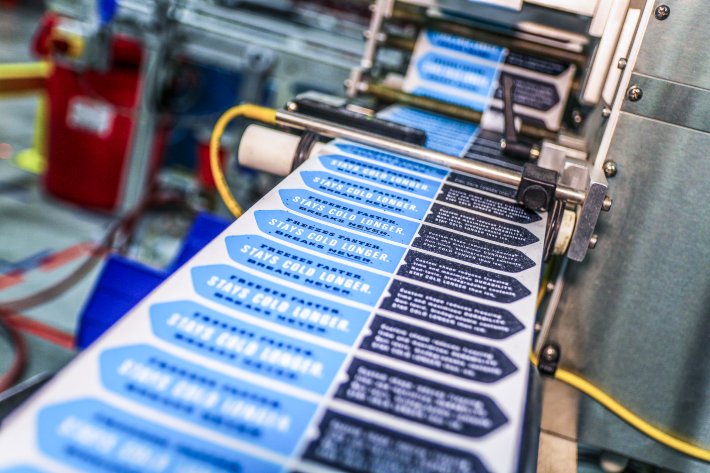

Comprehensive Post-Molding Services

We offer a wide array of finishing and assembly services under one roof. These include sonic welding, hot stamping, insert loading, post-production forming, date coding, labeling, custom packaging, and more. Our facility also houses a full paint line and booth for both high-volume and precision painting needs.

Integrated Production Workflow

Our team works closely with engineering and production departments to embed secondary operations into the overall process from the start. This reduces hand-offs and labor duplication, increases efficiency, and ensures a smooth transition between molding and finishing stages.

Customer-Specific Assembly & Customization

Whether you require fully assembled kits, branded components, or specialty configurations, we customize post-molding processes to match your exact needs. Our goal is to deliver completed parts that are production-ready the moment they leave our floor.