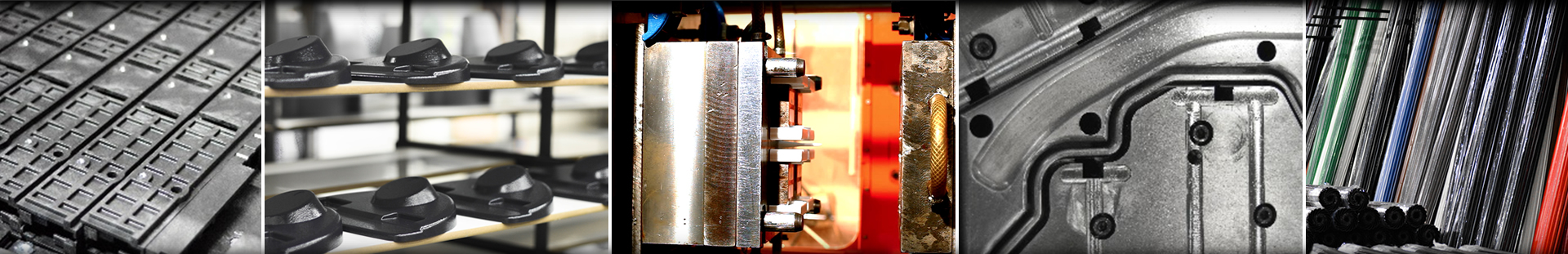

Manufacturing Services

The engineering of a plastic part affects more than just its good looks. It has an impact on the ease of manufacturing, dependability, performance, quality, and the cost to produce it. Engineering quality also determines how quickly the part can be introduced into the market, as well as being a driving factor regarding competitive advantage.

Planning your project means creating a strong concept that takes a number of factors into consideration including cost, production time, material, possible shape constraints, length tolerances, wall thickness, and added features. Each component of your concept determines not only the finished appearance, but whether the final product will perform as intended.

Custom Plastic Manufacturing Considerations

There are key factors that are instrumental in the success of creating a quality part that is cost effective. Creating a good concept is understanding the product application, market & performance level, and end-use objectives. Mold efficiency and performance must also be taken into consideration.

Regarding the molding process, up-to-date injection molding technologies, cycle times, and a solid material flow system need to be in place. Regulatory part-inspection and established part tolerance are both significant factors that will be affected by the assembly of the mold and end-product. Key considerations in your process should include:

Wall Thickness and Corner Details

A wall structure that is consistent in thickness helps ensure that material will flow equally and with consistent pressure through the die that allows for even cooling. An uneven wall thickness can result in bowing or distortion and may require additional tooling or cooling cycles, which can increase production time.

Sharp corners and notches can affect strength and durability by creating weak points in profile extrusions that may lead to breaking or cracking. Incorporating rounded corners into your mold can help prevent these issues.

Mating or Intersecting Parts

Projects involving mating or intersecting parts should include a sample piece to help facilitate proper fit and function.

Hollow Shapes and Details

Hollow shapes and other details can have an impact on product functionality, tooling costs, and production time. A sharp corner in a hollow extrusion, for example, could cause areas of weakness that can result in product failure. Hollow shapes also require additional modifications to the die to ensure proper material flow. These shapes can also complicate the sizing and calibration process.

Adding additional internal details should also be avoided with hollow shapes due to the added complexity and potential issues with keeping the details stable during the cooling process.

In-House Engineering & Tooling Services

Lomont Molding LLC (Lomont) has been providing premier manufacturing services since 1982. Our expertise, combined with innovative and cutting-edge technology, allows us to handle simple and complex projects of all sizes, and we pride ourselves on delivering quality product development and manufacturing.

Asking for assistance early in the process aids in planning manufacturing and helps detect complications that could cause issues during or after production. Our experienced in-house engineers use multiple CAD software programs to aid in engineering your next project, including:

- SOLIDWORKS®

- KeyCreator Direct

- Mastercam