Structural Foam

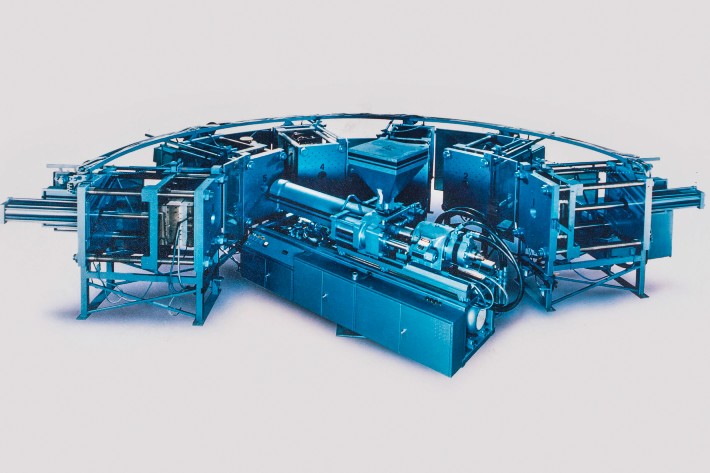

Structural Foam Molding for Large, Strong, and Lightweight Plastic Parts

Lomont’s structural foam molding process delivers high-strength, low-weight parts with reduced cycle times and minimal warpage.

Ideal for large or thick-walled components, our low-pressure process ensures durable, dimensionally stable results that outperform standard injection molding in cost and consistency.

Lightweight, Rigid, and Efficient: Structural Foam Molding for Demanding Applications

Lomont Molding offers specialized structural foam molding capabilities for customers requiring large, durable plastic parts without added weight or stress.

Originally established as a structural foam molder, we’ve built over 40 years of expertise into a highly efficient, low-pressure process that produces thick, sturdy components with consistent performance.

Our approach delivers cost savings, design flexibility, and high strength-to-weight ratios across applications in industrial, commercial, and transportation sectors.

Built for Strength, Scale, and Efficiency

Cellular Core Structure

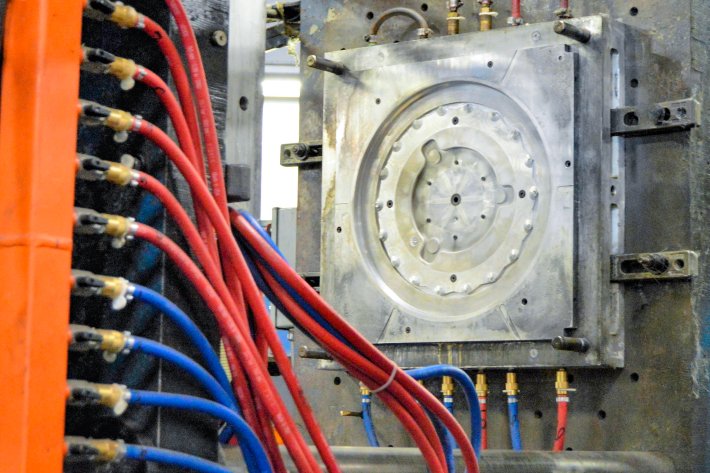

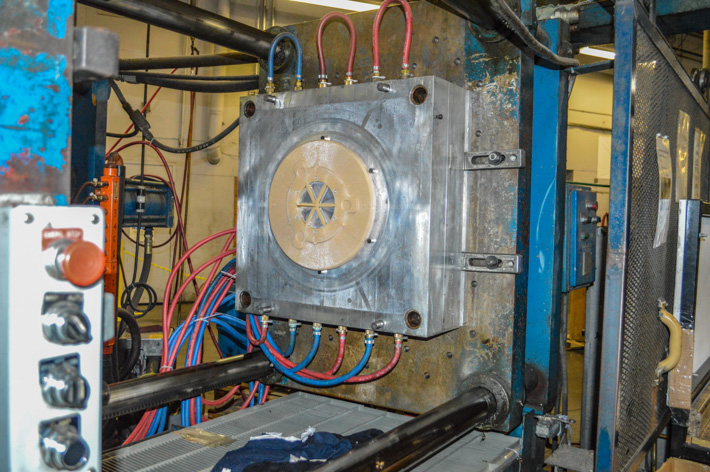

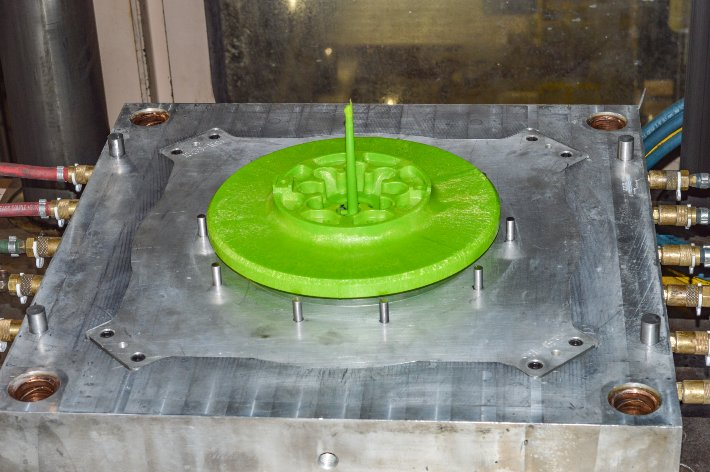

Structural foam molding creates parts with a solid outer skin and a cellular foam core, resulting in lightweight components with excellent strength-to-weight ratios and impact resistance.

In-House Secondary Capabilities

Our structural foam parts benefit from full-service secondary operations including a complete paint line and booth: providing added value, aesthetics, and post-molding enhancements all in one place.

Years of Expertise

Lomont Molding began as a structural foam molder, and we’ve continuously invested in growing that capability. Today, we offer our customers over four decades of trusted performance in structural foam molding.

Large-Part Capability

Our structural foam process is ideally suited for producing oversized and thick-walled parts that standard injection molding can’t efficiently handle, like enclosures, panels, and other heavy-duty applications.

Key Advantages of Structural Foam Molding

Design Flexibility

Enables large, complex parts with thick sections, integrated ribs, and features that would be difficult or cost-prohibitive in traditional injection molding.

Weight Savings

Reduces overall part weight without sacrificing durability. Ideal for applications in transportation, aerospace, and industrial equipment.

Enhanced Strength and Stiffness

Combines a solid skin with a foam core for excellent load-bearing ability and impact resistance, while also reducing vibration and noise.

Cost Savings

Uses less material and lower-pressure tooling, which helps lower part costs and tooling investments compared to solid injection molding.

Shorter Cycle Times

Faster cooling and lower pressures reduce cycle time, improving throughput and reducing lead times across production runs.