Over-Molding

Custom Over-Molding Solutions for Enhanced Functionality and Aesthetics

Our over-molding capabilities allow us to create integrated parts with improved grip, insulation, sealing, and comfort across industries.

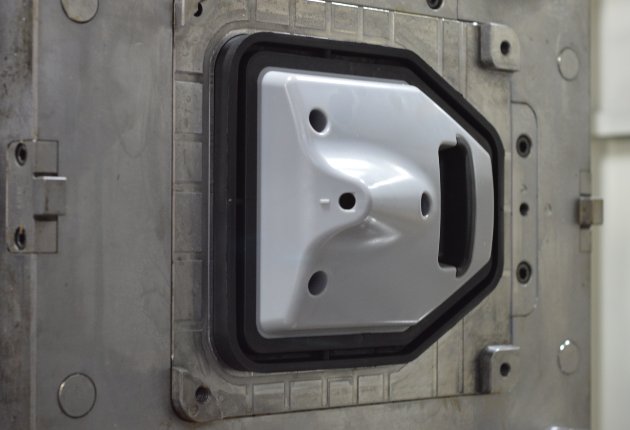

Precision Over-Molding for Multi-Material, High-Performance Components

Lomont Molding offers expert over-molding services that combine engineering precision with material versatility. By molding a second layer of plastic directly over a preformed component, we help customers create products with improved function, tactile feel, and protection.

Our over-molding process supports a wide range of materials, from rigid cores to soft-touch or protective overlays, enabling design flexibility and long-term product performance.

From industrial equipment and electronics to medical and consumer goods, we help customers elevate their parts through smarter material integration.

Over-Molding Applications and Capabilities

Versatility

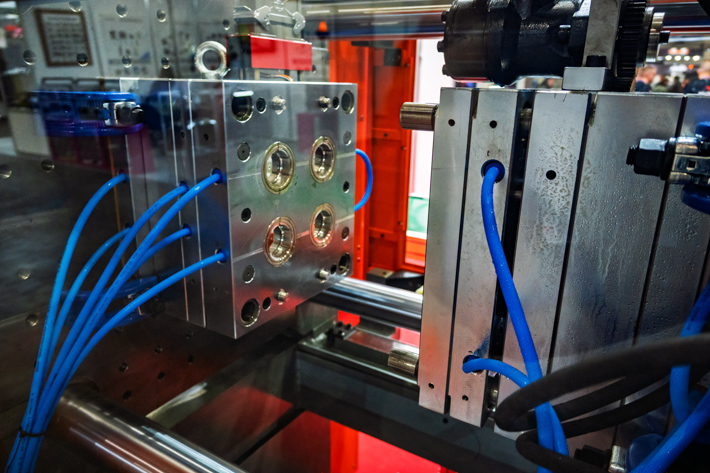

Because over-molding is often integrated into injection molding workflows, our broad experience with diverse processes, tonnages, and part sizes allows us to apply it across many project types and industries.

Increased Design Possibilities

Over-molding enables complex, multi-material designs that combine textures, colors, and features into a single component, offering more opportunities for visual and functional innovation.

General Uses

Ideal for adding grips, protected edges, soft-touch surfaces, or vibration dampening. Used across industries like electronics, automotive, healthcare, consumer products, and industrial manufacturing.

Efficient Integration

Over-molding streamlines production by bonding materials during molding, reducing the need for secondary assembly and improving part performance.

Key Advantages of Over-Molding

Improved Product Functionality

Enables integrated grips, seals, soft edges, or ergonomic contours for boosting usability and overall performance.

Noise & Vibration Reduction

Soft plastic over-layers dampen vibration and reduce noise, ideal for handheld tools, consumer electronics, and high-touch surfaces.

Improved Product Safety

Adds insulation, shock absorption, and anti-slip features to enhance safety in medical, industrial, or consumer-use environments.

Environmental Resistance

Over-molded materials can be selected for UV, moisture, temperature, or chemical resistance, helping extend product lifespan.

Assembly Simplification

Combining multiple functions in a single mold reduces part count, streamlines production, and cuts down on manual assembly.