Injection Molding

Your Complete Source for Custom Molding, Engineering, and Manufacturing Services

Injection molding is a low-waste, low-cost process that is suitable for production runs of any size, and the final product typically requires little to no finishing.

Our high-pressure plastic injection molding process is ISO 9001 Certified and is suitable for molding a wide range of materials.

Scalable, Precise, and Versatile Injection Molding Solutions

Lomont Molding delivers high-performance injection molding solutions backed by decades of experience, industry certifications, and cutting-edge equipment. Our ISO 9001 certified process supports complex part geometries, a wide range of materials, and production runs of any size; from short batches to millions of parts.

With advanced capabilities including overmolding, in-mold decorating, and gas-assist technologies, we’re able to solve design and manufacturing challenges across a range of industries.

Whether you need durability, precision, or scalability, we mold to your specifications on time and on budget.

What sets Lomont apart from the competition?

Process Diversity

Lomont Molding is proficient in multiple processes that supplement our Injection Molding capabilities, including but not limited to: Nitrogen & Gas Assist, Overmolding, and In-Mold Decorating.

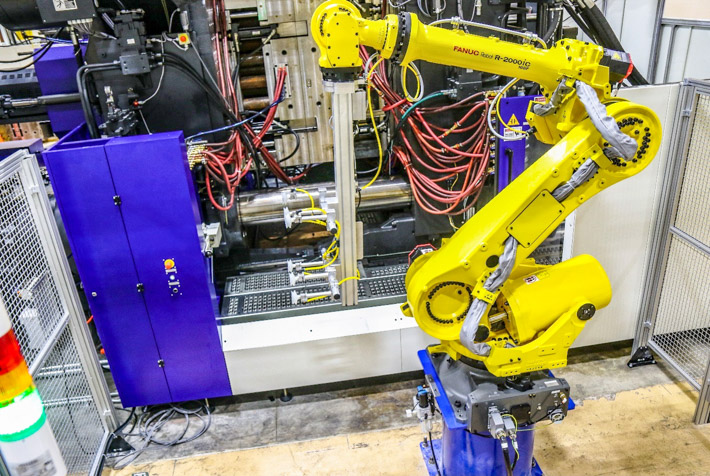

Large Tonnage Capabilities

We operate a wide range of equipment, including presses from 55-ton all the way up to 2700-ton. This allows us to offer more solutions for our customers than the average molder.

Expertise

Since 1989, Lomont has developed our Injection Molding expertise to become one of the top 100 injection molders in North America. Few molders offer as many in-house capabilities with the proven track record of Lomont Molding.

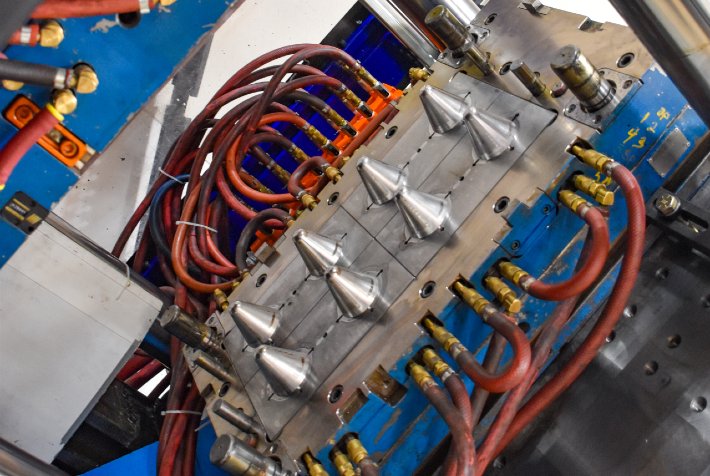

Tooling & Engineering Support

Our team collaborates closely with customers during the early stages of product development, offering design for manufacturability (DFM) guidance and tooling expertise. This ensures faster production launches, optimized part quality, and cost-efficient mold performance.

Key Advantages of Injection Molding

Production Scalability

Injection molding scales easily to your production needs. Once tooling is in place, the per-unit cost is extremely low and continues to decrease as volume increases.

Design Flexibility

Enables intricate, highly detailed parts with complex geometries. Multiple features can be integrated into a single mold to reduce post-processing and assembly.

Material Variety

Supports a wide range of materials including thermoplastics, elastomers, and some thermosets. Allows selection for strength, heat resistance, and chemical performance across industries.

Precision & Consistency

Produces tight-tolerance parts with excellent repeatability using advanced, computer-controlled systems, making them ideal for critical applications like medical or aerospace.

Strength & Durability

High-pressure injection creates dense, structurally sound parts that are resistant to wear; well-suited for automotive, industrial, and consumer product use.