About Us

Your Source for Custom Plastic Molding

Lomont Molding, LLC is a premier plastic molder offering complete in-house services including engineering, tooling, in-mold technologies, decorating, quality assurance, and secondary operations.

Since 1982, we’ve delivered high-quality molded products using a broad range of thermoplastics at our state-of-the-art facility.

Since 1982, Lomont Molding has grown into one of the leading custom plastic molders in the United States, offering a full range of services including engineering, tooling, in-mold decorating, assembly, and secondary operations.

Our success is rooted in our commitment to solving challenges through innovation and precision. Operating from a modern, high-capacity facility in southeast Iowa, we process a wide variety of thermoplastic resins using advanced molding technologies tailored to meet the needs of diverse industries.

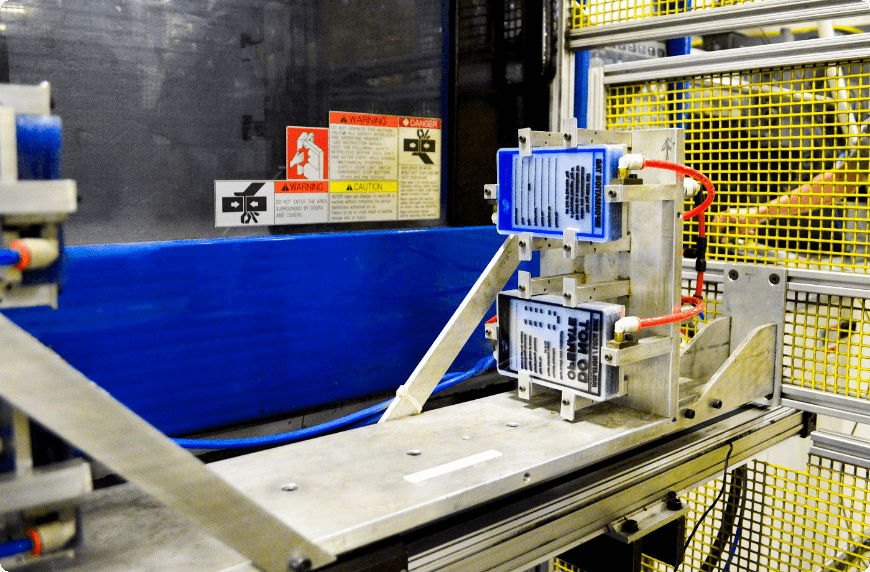

What sets Lomont apart is our ability to adapt and expand. Over the decades, we’ve invested in new technologies like nitrogen gas-assist, over-molding, and in-mold labeling, allowing us to support complex designs and deliver high-performance products at scale.

With proprietary product lines like Lomont IMT and Paragon Products, and a long-standing reputation for quality and service, we’re proud to serve customers nationwide with molded solutions that drive results.

Our Mission, Vision and Values

Our Mission

Lomont is dedicated to providing quality, service, and innovation that exceeds our customers’ expectations.

Our Vision

To become a profitable and respected industry leader through employee engagement, customer integrity, and innovative business practices.

Our Values

- Innovation – Creativity & tenacity to continually improve

- Integrity – Is foremost, and driver of our consistency

- Pride – For our quality work

- Respect – For our customers, each other, and our high standards

- Teamwork – The foundation of our excellence

Our History

1982

Founded in 1982 – Structural Foam Beginnings

Lomont began as a structural foam molding operation focused on producing durable, large-format parts. Over the years, we’ve grown significantly, expanding our capabilities, product lines, and in-house services.

1989

Injection Molding Expansion

In response to market demand and customer needs, Lomont added injection molding capabilities. Today, it represents our largest area of production.

2000

Incorporating Gas-Assist and Over-Molding

Lomont added nitrogen gas-assist and over-molding technologies to address more complex part geometries. These processes expanded the range of solutions we could offer customers.

2003

Pioneering In-Mold Decorating

Lomont began using in-mold decorating (IMD) to embed labels and graphics into molded parts. This advancement laid the foundation for our proprietary IMT product line.

2017

Expanding into Blow Molding

With the acquisition of the R&D Molders brand, Lomont expanded into blow molding. This brought with it nearly 50 years of combined experience and new capabilities for manufacturing hollow plastic parts.

Lomont Family of Companies

Lomont Molding LLC works together with our family of brands to deliver exceptional products and service across a range of industries.

Advanced safety signage and identification products using patented In-Mold Technology, revolutionizing the safety marking industry.

Industry leader in concrete and rebar accessories serving the highway, ready-mix, precast, and testing sectors.

Bringing decades of blow molding and injection molding experience across markets including medical, consumer, electronics, energy, and more.